Suspension Systems in Marine Pilot Chairs

Marine pilot chairs are integral to a vessel’s bridge for providing comfort, safety, and ergonomic support for operators during long navigational assignments. Suspension systems, particularly, define the quality and functionality of these chairs. In adverse sea conditions, suspension systems are critical in reducing vibrations, stabilizing chairs, and providing comfort.

Table of Contents

The Importance of Suspension Systems in Marine Pilot Chairs

Enhancing Comfort During Prolonged Operations

Vessel operations take long hours, during which one has to remain seated and maintain a high level of concentration. One of the greatest challenges of the job is the unpredictable and rough conditions. Continuous vibrations and movements are bound to result in discomfort, fatigue, and strain on the body. Suspension systems in marine pilot chairs provide the pilot with a level of isolation from the shock forces. These systems dampen the impact of waves and vibrations in the ship hull, resulting in a shift in gross discomfort on the pilot. Enhanced comfort in a job has the effects of increasing the level of concentration and efficiency. In a pilot’s case, the effects of reduced comfort result in the unacceptable outcome of fatigue.

Reducing Vibration and Shock Exposure

Vibration and shock are part of the everyday experience and are difficult to avoid onboard marine operations, particularly on high-speed craft, patrol boats, and offshore vessels. If vibrations are not suspended, they will transfer to the operator’s body, affecting posture, endurance, and long-term health. The suspension system reduces this problem by employing mechanical, pneumatic, or hydraulic means to absorb and dissipate the energy accrued prior to reaching an occupant. While this primary purpose is for comfort, it additionally serves to reduce cumulative stress injuries and allows the pilot to maintain a steady control on the navigation system to prevent unwanted pulsations or oscillations.

Improving Operational Stability and Focus

A properly defined, stable, and secure seating posture is essential to high-precision navigation and control of a vessel. The suspension system minimizes the movements of the pilot chair so last minute corrections due to vessel motion are avoided and operators can concentrate on the task at hand. The system achieves this via controlled damping to limit the vertical oscillations and lateral movements to appropriate ranges to eliminate the bouncing and swaying during a command or maneuver to ensure the task is accomplished. The operational safety of the vessel, and the efficiency with which the vessel is managed, are greatly improved with the precise control and command execution.

Ensuring Durability and Longevity of Equipment

Each piece of equipment will face harsh environments such as salt-water corrosion, temperature extremes, and mechanical stresses. A good-designed suspension system protects the pilot and increases the equipment’s durability. It lessens the mechanical wear on the chair’s joints, mounts, and base by decreasing the amount of vibration and shock the chair receives. To ensure the long-lasting reliability of the suspension system, manufacturers use marine-grade suspension system materials made with anodized aluminum and stainless steel. The system sustains human and mechanical endurance, confirming its important dual purpose.

Supporting Safety and Ergonomic Design

Every marine operation places the highest priority on the safety of those on board the vessel, and the suspension system plays a big part in this by promoting good posture and decreasing physical strain. While pilots are placed in safe and comfortable seats, they are able to respond quickly to sudden changes in navigation. Safety of the pilot and all those on board is enhanced during demanding maritime operations as the suspension system works to keep the pilot’s body aligned and supported throughout the task.

Types of Suspension Systems Used in Marine Pilot Chairs

| Type of Suspension System | Description | Key Advantages | Typical Applications |

| Mechanical Suspension | Utilizes metal springs and dampers to absorb shocks and vibrations through physical compression and rebound. | Durable, low maintenance, cost-effective. | Small vessels, patrol boats, and workboats. |

| Pneumatic (Air) Suspension | Uses adjustable air pressure to provide cushioning and adapt to the pilot’s weight and sea conditions. | Excellent comfort, adjustable firmness, superior vibration isolation. | Long-duration voyages, high-end yachts, and commercial ships. |

| Hydraulic Suspension | Employs fluid-based damping for precise control over movement and impact absorption. | Smooth response, consistent performance, ideal for rough seas. | Offshore vessels, high-speed crafts, and research ships. |

| Hybrid Suspension | Combines air and mechanical or hydraulic elements to optimize both comfort and stability. | Adaptive performance, customizable settings, enhanced shock absorption. | Modern control bridges and advanced navigation vessels. |

| Smart Suspension | Integrates electronic sensors and automatic adjustment mechanisms that respond to real-time vessel motion. | Intelligent adaptation, minimal vibration transmission, highest comfort level. | Next-generation marine vessels and digitalized ship bridges. |

Key Components of Suspension Pilot Chairs

It is time to identify and understand the importance of each component of the suspension pilot chairs in achieving functional and ergonomic value.

1. Shock Absorbers

Every suspension pilot chair contains shock absorbers. Their primary function is to dampen the effects of sudden movements due to the waves or vibrations of the vessel. They are able to convert kinetic energy to heat and to hydraulic pressure where the intensity of the shocks are lessened and the heat is generated. It assures that the pilot seat is comfortably smooth and stabilized even under extreme conditions of the sea. The comfort and quality of suspension shock absorbing pilot seats are improved, as the mechanical stress is maintained on the seat structure and its suspension points or mounting.

2. Springs and Airbags

Springs and airbags are the cushioning components of the suspension system. Steel and other composite mechanical springs are able to absorb vertical movement and balance the seat suspension under varying loads which is able to provide constant support. Pneumatic suspension systems use airbags and the users can change the comfort levels by adjusting the pressure of the air to their body weight and the sea conditions, which is used to enhance the suspension system. The custom seating experience is greatly used to improve the comfort and operating endurance of the sea pilot.

3. Dampers

Dampers are used in conjunction with springs or airbags to control the motion of the chairs. Their primary role is to avoid excessive rebound and oscillation after a shock is absorbed. In hydraulic or hybrid systems, with the aid of fluid dampers, the rate of movement is controlled, and the seat is allowed to be stable and responsive. This is invaluable for the rapidly moving, high-vibration marine environments which demand undistracted control from the pilot because the seat is designed to function in a way that allows the pilot to focus on the seat’s control.

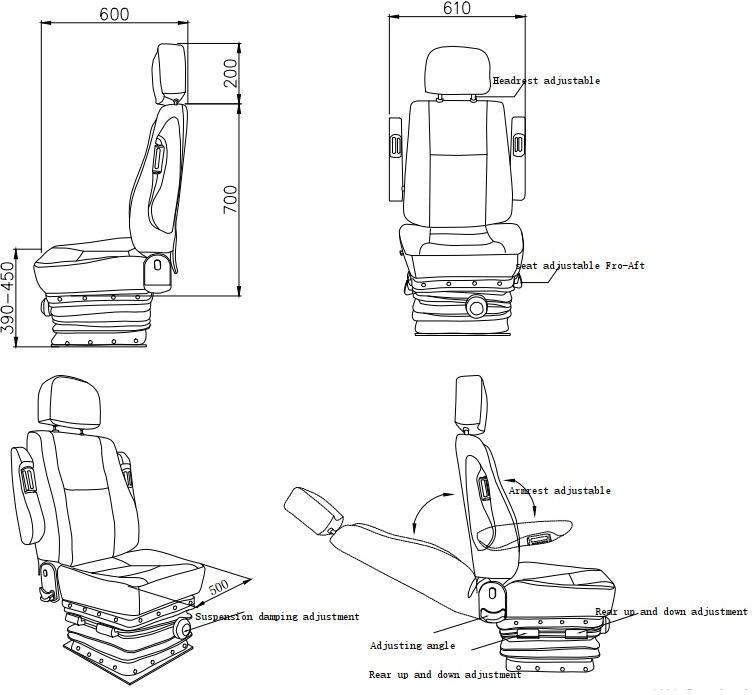

4. Height Adjustment Mechanism

The height adjustment mechanism is an important marine seat control because, in marine navigation, the height allows a pilot to achieve the precise line-of-sight and ergonomic seat alignment to the navigation instruments and the horizon. This is invaluable in operational efficiency during marine operations. Height adjustment may be manual, pneumatic, or electric. The important benefits of neutral body positioning are containerized posture and decreased discomfort during long neck and back strain, improving operational efficiency.

5. Swivel and Slide Tracks

Pilot chairs come equipped with swivel and slide tracks for enhanced mobility. The swivel feature gives the operator the ability to turn the seat effortlessly and gain access to control panels and communication systems positioned in various directions. The slide tracks allow the pilot to move the chair to and away from the desk navigation system and adjust their seat to any pre-determined position. This combination of features improves the routing and navigation of the workspace to reduce the pilot’s manual effort in the cramped quarters of the bridge.

6. Base Frame and Mounting System

The base frame and mounting system bear the primary structural responsibilities of the pilot chair’s suspension system. To minimize the effects of corrosion and mechanical strain, these components are made of marine-grade stainless steel or anodized aluminum. With the chair, they designed to firmly anchor to the flexibly absorbing vessel motions. Thus, challenging maritime conditions are the only conditions in which a suspension system is designed to operate, and the primary base components augments this by enduring damping and robust vibrations.

7. Control and Adjustment Interfaces

Current models of suspension shock absorbing pilot chairs come equipped with control systems that allow operators the ease of adjusting the chair to individual preferences. These adjustments can be made via pneumatic control systems, hydraulic dampers, and electronic adjusters that allow users to save their preferred settings. Pilots can be provided with consistent comfort by allowing them personalized control over adjustments to the suspension, the chair height, and the angle of the backrest. These active systems aim to provide a fully automated comfort experience that suits a person’s individual characteristics.

Engineering Considerations of Suspension Pilot Chairs for Marine Environments

| Engineering Consideration | Description | Purpose | Common Design Approaches |

| Corrosion Resistance | Exposure to saltwater and humidity can cause metal components to corrode. | Ensures long-term durability and reliability in marine conditions. | Use of marine-grade stainless steel, anodized aluminum, and anti-corrosive coatings. |

| Vibration and Shock Isolation | Continuous wave motion and engine vibrations affect operator comfort and equipment lifespan. | Reduces operator fatigue and prevents structural damage. | Integration of advanced damping systems, elastomer mounts, and multi-stage suspension mechanisms. |

| Material Strength and Weight Optimization | Marine environments demand strong yet lightweight materials for performance and stability. | Balances strength with ease of installation and movement. | Use of high-strength alloys, composite materials, and optimized frame geometry. |

| Sealing and Water Protection | Moisture and salt ingress can damage suspension components and internal systems. | Protects internal mechanisms from corrosion and malfunction. | Sealed hydraulic or pneumatic units, waterproof seals, and enclosed adjustment mechanisms. |

| Thermal Stability | Marine temperatures can fluctuate significantly depending on operating region. | Maintains consistent suspension performance and operator comfort. | Selection of temperature-tolerant materials and fluid-stable hydraulic systems. |

| Ergonomic Design Compatibility | The chair must support correct posture and adjustability for various operators. | Improves comfort, reduces strain, and enhances navigational efficiency. | Adjustable seat height, lumbar support, armrest positioning, and tilt mechanisms. |

| Mounting and Stability | Pilot chairs must be securely fixed yet flexible enough to absorb motion. | Ensures safety and balance during vessel operation. | Reinforced base plates, vibration-isolating mounts, and flexible deck anchoring systems. |

| Ease of Maintenance | Marine chairs require regular upkeep under limited onboard conditions. | Extends product life and minimizes downtime. | Modular suspension designs, quick-access panels, and corrosion-resistant fasteners. |

| Compliance with Marine Standards | Chairs must meet maritime safety and design regulations. | Ensures safety certification and operator protection. | Adherence to ISO, IMO, and DNV marine standards and testing protocols. |

Innovations in Suspension Technology for Marine Pilot Chairs

Innovative suspension technology for pilot chairs combines comfort and performance offering advanced intelligent engineering adaptive design.

1. Smart Suspension Systems

Suspension systems designed with smart technology have transformed marine pilot chairs. Sensor systems monitor in real-time and automatically adjust chairs to compensate for dimensional changes arising from tides, waves, and vibration, and ensure stability and comfort. Microprocessor control systems allow automatic seat behavior adjustment for safe operations and reduced strain while working for long periods.

2. Integration of Pneumatic and Hydraulic Hybrid Systems

Hybrid suspension systems are yet another major advancement for the marine seating technology. With the integration of pneumatic cushioning and hydraulic damping, a system can be designed to efficiently combine comfort and control. The pneumatically adjustable cushioning system can be tailored to the operator’s weight and preferences, while the hydraulic system circuit provides stable and seamless control of system motion. Shock absorbing systems designed for high-speed vessels and offshore operations to be used in rapidly changing conditions are highly adaptable and provide superior shock absorption, as offshore high-speed vessels require rapidly changing responsive systems and adaptable cushioning for sustained comfort.

3. Use of Advanced Materials

The use of new materials for marine captain’s chairs has had a positive impact on suspension systems. With the new lightweight composites, high-strength alloys, and corrosion-resistant polymers, the suspension system’s steel parts can be replaced, and system maintenance can be improved. The suspension system can be exposed to the harsh marine environment, particularly saltwater, to improve lifespan of the system while reducing weight for improved maneuverability and ease of installation. Self-lubricating bushings and wear-resistant coatings can also be applied to improve maintenance for extended periods of operation.

4. Electro-Mechanical Adjustment and Control Systems

Modern pilot chairs on marine vessels are incorporating electro-mechanical systems which allow effortless fine-tuned suspension adjustments. Compact actuators set under suspension miniature systems allow operators to adjust suspension stiffness, seat height, and damping sensitivity through touch control systems. These systems further incorporate memory functions which store adjustable parameters in order to help pilots quickly return to positions of optimal ease. The convenience offered in such systems is significant, especially and in conjunction with the use of automation and smart control in the digitalized integration of ship-bridge systems.

5. Vibration Isolation and Noise Reduction Technologies

Vibration isolation has been an area of focus in suspension systems for marine chairs. The use of multi-layer damping materials in combination with tuned mass dampers is becoming the ‘state of the art’ in the integration of modern suspension systems to help reduce the passage of distracting vibrations from a vessels deck. These improvements help create an environment that is quieter and more focused, which is especially useful in the performance of modern routing and communication tasks.

6. Modular Suspension Platforms

Suspension technology has also progressed pertaining to maintenance efficiency. Modular suspension platforms enable rapid replacement or upgrades of certain parts without the need to disassemble the entire chair. Such a design philosophy facilitates onboard servicing, which is of great importance to commercial and military vessels that operate under strict timelines. In fact, some systems have incorporated diagnostic sensors which inform operators or maintenance personnel of the need to examine certain parts or make adjustments.

7. Sustainability and Energy Efficiency in Suspension Design

Suspension systems are no different in this respect, and there is no doubt that sustainability has emerged as a topic in marine engineering. This is evidenced by the manufacture of pneumatic systems which incorporate systems that achieve hydraulic energy efficiency, use biodegradable fluids, and reduce overall environmental impact. This is further evidenced by the use of closed loop recyclable materials and modular designs, which facilitate circular manufacturing and the bowed performance of marine captain’s seats. Designed systems ensure that vessels operate within the established performance parameters as they achieve sustainable and environmentally friendly goals.

Final Thoughts

The suspension system is the foremost element that contributes to the comfort and functionality of a marine pilot chair. Regardless of whether it is mechanical, pneumatic, or hydraulic, the system shields the operator from the battering marine dynamics while allowing them to maintain focus, balance, and stamina. As the designs of vessels adapt to more ergonomic and technologically enhanced solutions, sophisticated suspension systems will continue to be pivotal in improving the comfort of the operator and the safety of navigation.