Customized Mooring Bollards for Offshore Floating Terminals

Offshore floating terminals, including FPSOs, FSOs, FLNG facilities, and ship-to-ship transfer units, operate in some of the most demanding maritime environments. In these situations, mooring bollards are vital safety elements designed to withstand extreme dynamic loads, variable line angles and harsh environmental conditions. Customizing mooring bollards for offshore floating terminals ensures not only operational reliability but also long-term longevity, crew safety and compliance with stringent industry standards.

Table of Contents

Why Customized Mooring Bollards are Essential for Offshore Floating Terminals

1. Adapting to Harsh Offshore Environments

The floating docks are located in open oceans in which the winds, waves and currents are considerably more agressive than in protected ports. These forces of nature cause continuous motion for both the terminal and the moored vessel producing dynamic loads much higher than the ones experienced by traditional dockside anchoring. Marine mooring bollards that are customized designed to withstand these conditions, with greater strength, a higher degree of durability, strength and resistance to fatigue and long-term durability.

2. Handling Complex Mooring Dynamics

As opposed to fixed berths, floating terminals off the coast experience constant shifts in vessel positions. Mooring lines are exposed to different angle of lead, vertically and horizontally when the ship and terminal shift in relation to one another. Bollards that are standard do not have the right design for this wide range of angles. This can result in rope wear and reduced holding capacity. Bollards that are custom-designed are shaped and designed to fit different lead directions, without causing damage to the rope mooring lines.

3. Optimizing for Limited Deck Space

Layouts for decks and platforms on offshore are packed with safety equipment, process equipment mechanisms, crew routes. This means that bollards need to be small but capable of handling heavy load. Modifications allow for more space-efficient designs that seamlessly integrate into existing deck configurations which can include bollards and fairlead roles to eliminate the requirement for fittings with multiple components.

4. Enhancing Corrosion Resistance and Longevity

Marine environments can accelerate corrosion particularly in the tidal and splash zones. Bollards for offshore use more than the standard coatings. They typically have Thermal Spray Aluminum (TSA) and Multi-layer epoxy system, or replacement wear sleeves to protect high-contact areas. Customized solutions are also designed to work of cathodic protector systems in order to prolong the life of the service in harsh seawater conditions.

5. Supporting Operational Safety and Efficiency

Offshore mooring must usually be conducted in harsh conditions, and with a limited amount of time for securing and releasing lines. Custom-designed bollards come with high-quality profiles that are free of snags with ergonomic heights and smooth surfaces, making lines handling easier and safer. In certain cases integrated load monitoring systems give live tension information which allows workers to adjust their settings in a timely manner and avoid overloading situations.

6. Meeting Project-Specific Requirements

Each floating terminal offshore is different, and has unique conditions for the environment vessels, types of vessels, and operating patterns. A standard bollard is not able to address these issues efficiently. By adjusting the bollard’s dimensions, geometry, materials and coatings for the particular project operators can achieve higher performance, lower maintenance costs, and enhanced security throughout the terminal’s operating time.

Key Engineering Considerations for Custom Designs in Mooring Bollards

Designing customized mooring bollards requires a precise balance between strength, durability, ergonomics and long-term maintainability.

1. Load Capacity and Safety Factors

The first step in custom design for mooring bollards is to determine the load capacity. Engineers need to determine the safe Working Load (SWL) and the maximum mooring force expected depending on the size of the vessel and mooring arrangements, as well as environmental loads like waves, winds and currents. Heavy-duty and offshore applications usually require the consideration of the effects of vessel movement. Safety measures are applied according to applicable standards–such like PIANC, BS, or OCIMF guidelines – to ensure that the bollard can withstand situations that are extreme, but not without causing damage or failure.

2. Load Direction and Mooring Geometry

Bollards are not just subject to forces that are directed in a single direction. In many locations, particularly offshore, lines travel at different vertical and horizontal angles. The design of the bollard’s head neck and the base have to adapt to these angles while avoiding lines from sliding or wearing excessively. For instance, bollards at floating terminals might require a load-bearing capacity of 360 degrees and those located in restricted berths might have to deal with the steep vertical leads of high tide ranges.

3. Fatigue Resistance and Structural Integrity

The repeated loading and unloading of cycles could lead to the failure of fatigue in time, particularly around stress points like welds and transitions between sections. Custom bollard designs typically include seamless fillets and radii, as well as large radius and a streamlined profile for welding to minimize stress risers. FLEA, or Finite Element Analysis (FEA) is utilized to simulate load situations and to identify areas that require reinforcement or adjustment of material thickness in order to attain the desired longevity of the material, usually up to 20 years for marine use.

4. Material Selection and Metallurgy

The decision between ductile iron or fabricated steel will depend on the load requirements production capabilities, as well as costs. Offshore environments and cold climates may require low-temperature-tough steels to prevent brittle fracture. The metallurgy should guarantee high tensile strengths and excellent impact resistance and high weldability in cases where fabrication is required. For areas that are highly corrosive using high-quality stainless steel and advanced alloys in wear-prone zones may be justified.

5. Corrosion Protection Systems

Marine environments–especially splash zones–are highly aggressive toward steel structures. Custom bollards typically utilize a multi-barrier security approach, which could include the use of thermal spray aluminum (TSA) as well as zinc-rich primers and epoxy build coats as well as polyurethane-based topcoats. When bollards are constantly exposed to seawater immersion the integration of the cathodic system of protection (either the sacrificial anode or the imprinted current) is vital. Wear sleeves that are replaceable or collars that protect the bollards will prolong the service life in areas that have high contact.

6. Foundation Design and Integration

The bollard’s capacity to handle load is only dependent on its foundation. Engineers must make sure that the jetty, deck or dolphin structure underneath the bollard can carry the loads applied to it into the structure supporting it without stressing. When it comes to offshore platforms this could include shear-keyed bases anchor bolts with high strength or direct integration into deck plating made of steel, which is secured by reinforced girders. Foundation designs should also permit easy inspection and replacement without requiring extensive structural changes.

7. Ergonomics and Operational Safety

Customized bollard designs should ensure an efficient and safe line handling of crew members. This means selecting the appropriate head diameters that match rope sizes, as well as ensuring smooth and free of snags, and placing bollards in a way that allows for accessibility without obstructions to walkways. For offshore operations where speedy release and mooring are crucial bollards could be constructed with flared or horned designs to aid in rapid line capture as well as secure hold. High-visibility decks with anti-slip interfaces and high-visibility marks improve the safety of vessels in wet or low-light conditions.

8. Integration of Smart Monitoring Technologies

Modern custom bollards may be equipped with sensors that detect line loads in real time as well as detect lead angles and track the structural strain. These systems can be used to predict maintenance, increase mooring safety and supply operators with crucial information for making operational decisions. Integration with a facility’s management and monitoring system assures that the possibility of overloads or other abnormal conditions are identified early which reduces the possibility of a mooring failing.

9. Maintainability and Lifecycle Planning

The design of the bollards to be easy to maintain is a key feature of high-quality custom mooring bollards. It could include modular designs that allow for rapid replacing, ports for inspection to conduct tests that are non destructive (NDT) and even wear parts that can be removed. Lifecycle planning will ensure that the bollard is functional for a long time and with predictable inspection intervals and well-defined spare parts plans.

Common Custom Mooring Bollard Types for Offshore Floating Terminals

| Bollard Type | Description | Key Advantages | Typical Applications |

| High-Capacity Single-Bitt Bollard | Large, thick-walled drum that has a the smooth crown radius to support high horizontal and multi-directional loads. | Compact footprint, high horizontal load capability, and reduced wear on the rope. | Offshore terminals that have a small decks and strong dynamic forces. |

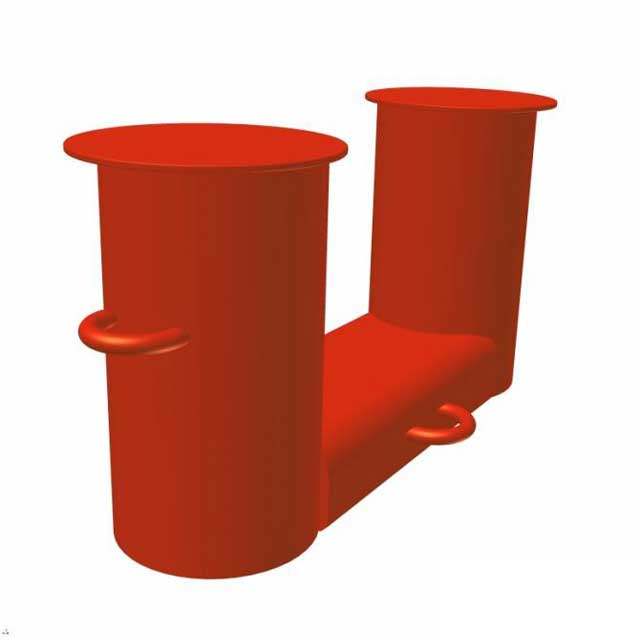

| Double-Bitt Bollard (Modified Heads) | Two vertical posts, each with a customized head diameters as well as spacing for multiple lines to secure. | Securely belaying multiple lines, which reduces lines crossing. | Mooring side-by-side in FPSOs or FLNG units. |

| Horned or Hybrid Bollard | Horn shapes that are extended for rapid rope capture and a controlled release. | More efficient mooring operation, reduced staff handling time. | STS transfer processes and terminals that require quick line modifications. |

| Fairlead-Integrated Bollard | It combines fairlead and bollard functions and features built-in guides or rollers. | Reduces the need to have separate fairleads, reduces rope chafing. | Offshore platforms with deck layouts that are tight. |

| Shear-Keyed Base Bollard | Base is designed with interlocks or shear keys to ensure the transfer of load to deck structures. | Structural stability improved, simple replacement. | Modular decks or replacement offshore modules. |

Installation and Maintenance in Customized Mooring Bollards Used for Offshore Floating

| Aspect | Key Considerations | Benefits |

| Foundation Preparation | Check for deck reinforcement or structural integration prior to bollard installation Check alignment with the layout of mooring. | It ensures a secure transfer of load and avoids structural damage. |

| Base Fixing Method | Utilize shear-keyed bases, anchor bolts that are high-strength or welded connections for stability that is offshore grade. | Enhances the structural integrity as well as resistance to the force of dynamic load. |

| Corrosion Protection During Installation | Install protection coats (e.g., TSA, epoxy) prior to marine bollard installation; ensure the integrity of the coating throughout handling. | Enhances the life of your service in marine environments. |

| Sensor Integration | Install strain gauges that have closed wiring and IP68-rated connectors. | It allows real-time monitoring and prescriptive maintenance. |

| Access for Inspection | Design with easy access points for visual inspections and NDT. These include cover-ups that can be removed or inspection ports. | It simplifies routine inspections and thorough checks. |

| Replaceable Wear Components | Install stainless steel or hardened alloy sleeves into high wear zones for quick replacement. | Lowers the cost and time of repairs. |

| Regular Maintenance Schedule | Perform annual visual inspections periodically, conduct NDT checks, and a 5-year overhaul that is aligned with the requirements of your class or flag. | Assists in maintaining operational security and ensures conformity. |

| Spare Parts Strategy | Make sure you have the most critical spare parts (sleeves bolts, sleeves modules) available for immediate replacement. | Minimizes operational disruption during failures. |

Future Outlook of Customized Mooring Bollards for Offshore Floating Terminals

As vessels grow larger and mooring conditions become more complex, customized mooring bollards are advanced to meet higher safety, durability, and operational efficiency standards. Future developments for these marine bollards will be shaped by advancements in materials, engineering and the developments of digital technologies.

Increasing Demand for High-Capacity Designs

With the increasing popularity of super-large crude transporters (ULCCs) along with floating storage and regasification unit (FSRUs) Bollards for mooring will have to be able to handle larger load moorings. The design of custom designs will be focused on better load distribution and structural integration that is enhanced and fatigue resistance to ensure a long service life in tough marine environments.

Adoption of Advanced Corrosion-Resistant Materials

Materials that are innovative, like stainless steel duplex super austenitic and super austenitic alloys and hybrid composites will grow in popularity. These materials will offer superior resistance to corrosion, lower maintenance requirements, and a high mechanical durability, even in harsh offshore conditions.

Modular and Retrofit-Friendly Designs

Future custom bollards will be built to be modular that allows for simpler upgrade, retrofits, or repairs that do not require extensive modifications to the structure. This flexibility is crucial as offshore terminals adjust to the changing size of vessels and operational requirements.

Conformity to Stricter Safety Standards

The global maritime organisations as well as classification societies will establish stricter performance and safety requirements. Custom-made mooring bollards are expected to include higher safety elements such as redundancy, features for redundancy, and process verification to meet the changing requirements for compliance.

Sustainability and Environmental Considerations

The use of eco-friendly coatings, low-impact production methods, and the recyclability of materials will become the norm. Offshore operators will prefer designs that will reduce their footprint on the environment, while still delivering the performance.

Summary

Customized mooring bollards for offshore floating terminals are specifically designed to meet the unique operational, environmental, and safety demands of offshore environments. By carefully tailoring load capacity, geometry, materials, coatings, and smart monitoring features, operators can enhance mooring reliability, extend service life and reduce operational risks. When it comes to offshore mooring, an appropriately designed marine mooring bollard is essential for safe and efficient terminal operations.