How to Choose the Right Marine Bollard Type for Different Ports and Vessels

Every port and ship across the world absolutely requires a marine bollard. Screwed into the ground, a marine bollard is used to secure a ship’s mooring lines in place of the head of the ship and acts as a resistance against the dynamic forces of the environment. Failing to use a high-quality marine bollard can endanger a ship, a port, and the people working close to the port.

This article reviews the most common marine bollard types, discusses the features of their design, and reviews their effectiveness in different situations.

Table of Contents

Fundamental Selection and Design Principles of Marine Bollards

The proper selection of any mooring bollard is fundamentally rooted in rigorous engineering analysis, primarily focusing on load calculation and structural resilience.

1. Load Determination and Safety Requirements

Before you do anything else, you need to make sure you know the Safe Working Load (SWL) and Ultimate Working Load (UWL) for the bollard. To do this, you need to look at the following criteria:

- Vessel Tonnage: The largest ship that will be at the dock will set the minimum load that the bollard will need to be able to hold.

- Environmental Loads: Make sure to check for the site’s maximum wind speed, current speed, and potential wave forces for the most extreme weather the area is at risk for.

- Safety Margin: International regulations (PIANC, OCIMF) state that you need to have a large safety factor to be in compliance. This is done by ensuring that the SWL is significantly lower than the actual yield strength of the material.

2. Structural Integrity and Anchorage Design

A bollard system is only as strong as its weakest link. For most systems, the weakest section is the connection to the dock structure. The Design Principles must address both the shape of the pillar and its fixings:

- Geometry of the Design: The modern bollard, T-Head, and Horn are most often shaped with Design FEA to achieve optimal load distribution and reduced stress concentration zones under eccentric loading.

- Anchorage Design: The anchor bolts are a non-sacrificial, critical consideration. The total tensile and shear forces that must be transferred from the bollard body to the underlying concrete or steel dock structure must be calculated to avoid pull-out or shear failure. This is achieved with accurate estimates of the quantity, diameter, and embedment depth of the configuration.

- Choice of Material: There must be a compromise of strength vs cost vs durability. For high capacity applications, Cast Steel is preferred as it is much stronger. For a moderate load, Ductile Iron is a more economical option.

Marine Bollard Types, Benefits, Application, and Selection Advice

Different marine bollard types are distinguished by their geometric profiles, which directly dictate their rope-holding capacity, allowable mooring line angles, and overall maximum capacity.

| Marine Bollard Types | Structural Features | Suitable Applications | Advantages | Selection Advice |

| T-Head Bollard | The T-shaped head allows mooring lines to be secured from multiple directions. This design provides strong resistance to twisting forces and distributes load more evenly across the bollard body. | 1. Deep-water commercial ports 2. Container terminals 3. Bulk cargo terminals 4. Oil tanker berths 5. Ports with strong winds or tidal currents | 1. Excellent multi-directional strength 2. Suitable for high-capacity loads (50–200 tons) 3. Very stable under heavy tension | Port operators handling large commercial vessels should prioritize T-Head bollards. Due to their size and installation requirements, designers must ensure sufficient concrete foundation capacity. |

| Horn (Staghorn) Bollard | Horn bollards feature two upward-curved arms that resemble antlers. This shape allows lines to be wrapped easily and accommodates multiple mooring angles. | 1. Multi-purpose port terminals 2. Ferry and passenger terminals 3. Medium-size cargo berths 4. General waterfront infrastructure | 1. High flexibility for varying rope angles 2. Very convenient for quick tie-up and release 3. Suitable for a wide range of vessel classes | If the port is required to accommodate various vessel types without specialized mooring equipment, the Horn (Staghorn) bollard is the most practical choice. |

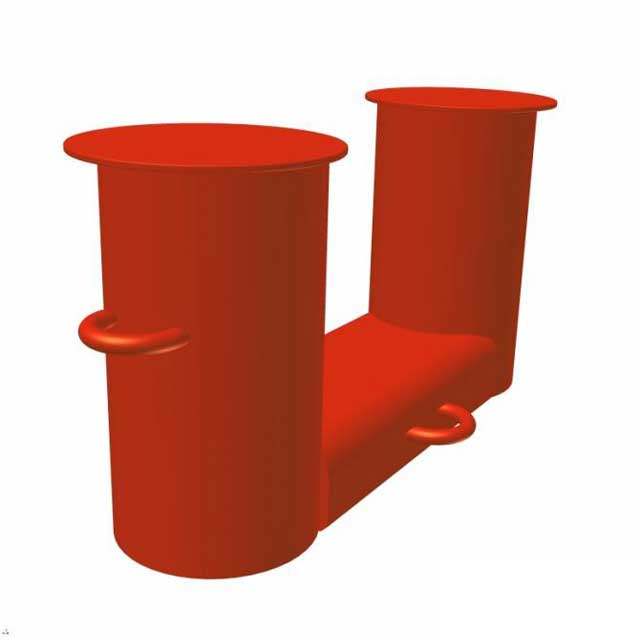

| Double-Bitt Bollard | Double-bitt bollards feature two parallel posts, making them ideal for controlling line friction and allowing crew members to adjust mooring tension efficiently. This design is typically installed on the vessel, rather than the dock. | 1. Workboats 2. Tugboats 3. Passenger vessels 4. Luxury yachts 5. Medium-sized ships | 1. High precision in controlling rope tension 2. Easy operation 3. Superior corrosion resistance when using stainless steel | For vessel builders, stainless steel Double-Bitt bollards are recommended due to their long service life, mechanical reliability, and aesthetic appeal. |

| Pillar Bollard | Pillar bollards consist of a single vertical column and are widely used for light to medium mooring loads. | 1. Yacht marinas 2. Fishing ports 3. Club piers 4. Small commercial docks | 1. Compact footprint 2. Low cost and easy installation 3. Low maintenance requirements | Due to lower load capacity, Pillar bollards are not suitable for large vessels or high-energy mooring conditions. |

Material Selection: Stainless Steel, Cast Steel, Ductile Iron, and Composite Bollards

1. Stainless Steel Bollards

Boat bollards made of stainless steel, like 304 and 316 grades, are very corrosion-resistant and are best for areas that are high in salt and very humid conditions, like the sea. Top quality steel is used in yacht marinas, high end docks, and other seaside locations that need steel that looks good and is very tough. Stainless steel is smooth, so it will not wear the ropes down. Because it will not need to be repainted and will not rust, it will require less maintenance. Also, stainless steel will last a long time, so it is very reliable and is affordable in the long run. Even though the initial prices for the steel are high, it is better than the prices for less durable cast metals.

2. Cast Steel Bollards

Cast steel bollards are designed for heavy-duty commercial and industrial ports for large cargo vessels like tankers, which apply great mooring forces. They have great tensile and compressive strength and thus are stable in the presence of multi-directional forces. Cast steel bollards are designed for installation on reinforced concrete and are capable of enduring extremely high fatigue mooring activities. They cost less than SS, and with coatings like epoxy and galvanisation, they get good corrosion resistance. This type of bollard is fitted for deep-water terminals, oil and gas ports and other high mobility maritime installations that have main concern primary structural strength.

3. Ductile Iron and Composite Materials

Ductile iron bollards are a decent option that is on the cheaper side. It is good for fishing ports, smaller marinas, and medium-load docks. Maintenance is often needed, though, and it is a bit harder to install. There are other materials, like composite, that are lightweight, but they are more expensive. They also have high resistance to corrosion and don’t need maintenance for a while. It is a great choice for instances when weight is an issue. Engineers need to keep everything in mind when designing a bollard so it is functional and while also getting the best value from it.

How to Choose the Right Marine Bollard

1. Match by Vessel Type

When beginning the selection of marine bollards, the first step is to analyze the types of units that may berth at the dock. Large cargo and tanker-sized vessels bring in considerable mooring forces, which lead to the demand for heavy-duty T-Head or Kidney bollards as they are able to withstand and distribute load in multiple directions. Medium-sized vessels like ferries and bulk carriers can be accommodated using Horn or Staghorn bollards as they provide operational flexibility in regards to the angle of the ropes. Small marine and yacht pillars and stainless-steel bollards have a load capacity that is adequate, but they may be aesthetically pleasing and are easier to handle. Corrosion resistance and overall load capacity with an appealing design are ideal for recreational docks and marinas.

2. Match by Port Structure

Also, within a port’s structural characteristics, what type of bollard is optimal will also vary. For large deep draft commercial ports, there is a need for high-lever load bollards placed on reinforced concrete bases that can hold heavy mooring loads. For multi-purpose terminals that handle veracious sized vessels, there is a capability of using horn bollards, as they provide more operational flexibility and quicker mooring and unmooring. For light duty small piers or small marinas that hold leisure craft and fishing vessels, pillar bollards are optimal as they are smaller, easier to install, and possess a moderate load capacity.

3. Consider Environmental Forces

Gives environmental considerations like tidal range, wind strength, and waves a role in choosing bolkards. Strong tides, bolkards with high strength coupled with a large safety factor and robust foundation, and storm bolkards needed more with sudden cracks. The block position matters in the bypassing, no rope and line slipping, and uneven slack and components orientation. The listed factors lessen maintenance, enhance safety on the moored, and avoid downtime in case of the bollards snapping.

4. Evaluate Maintenance and Budget

Choosing materials plays a major role in maintenance and expenses for the future. Stainless steel bollards work well for expensive marinas and premium yacht berths since they are corrosion-resistant and need little maintenance, as they won’t require regular painting. Cast steel bollards are a great option for commercial docks and harbors with a lot of heavy traffic because they are very strong and are perfect for the price range. Ductile iron bollards work for the light duty bottom of the price spectrum, though they do need to be checked in harsher conditions of the ocean. Finding the right spot in the middle between initial expenses and lifespan, with the operational needs always leads to the best value.

Final Thoughts

Picking the correct marine bollard is really important for the safety of the mooring and the efficiency of the port and marinas. For example, the T-Head Bollard is heavy duty and the other is a boat bollard made from Stainless Steel and is made for luxury marinas. There is a variety of marine bollards, all of which differ and are more advantageous in different marine conditions. Having knowledge of these bollard types and understanding the principles of correct and applicable design and material will help the reliability of mooring operations and will increase the safety of all mooring operations.