High-capacity Mooring Bollards for Ultra-large Vessels

As the maritime industry evolves, the size and capacity of vessels will continue to grow, requiring improvements in port infrastructure to ensure the safety and efficiency of operations. Ultra-large container vessels, with capacities that exceed 20000 TEUs require mooring solutions capable of withstanding immense forces. High-capacity mooring bollards are crucial in this infrastructure, specifically designed to handle the enormous loads imposed by ultra-large vessels while ensuring safety and operational efficiency.

The Needs for High-capacity Mooring Bollards

Ensuring Safety Under Extreme Forces

Large vessels put a lot of pressure on mooring lines as a result of their displacement of wind, current and tidal force. Without properly-designed marine bollards the chance of failing lines, damage to hulls or dock structural damage is increased drastically. Bollards with high capacity provide the security to protect vessels even in extreme weather conditions, securing the vessel as well as the port infrastructure.

Accommodating Growing Vessel Sizes

The growing size of vessels require the use of mooring systems that can handle more force. As the size of ships increases as do the strains placed on mooring points. Bollards that are built to capacity take on the increased demands and ensure that ports are in a position to service the future generation of mega-ships effectively and securely.

Enhancing Operational Efficiency

Effective mooring operations are essential for speeding up turnaround time at ports. Bollards with high capacity allow multiple line to be secured at the same time and make mooring simpler. Their robust design minimizes the need for readjusting and enhances the overall reliability of operations essential in ports with high traffic.

Preventing Infrastructure Damage

Dock structures are under a lot of stress when dealing with vessels that are large in size. Unsuitable mooring solutions could cause structural damage, expensive repairs, and even disruptions in operation. Marine mooring bollards help to distribute the force more efficiently across the foundation of the dock, reducing the chance of damage and prolonging the useful life of the port infrastructure.

Key Design Considerations for High-capacity Bollards

Designing high-capacity mooring bollards requires a careful balance of structural integrity, material selection, environmental considerations, and operational efficiency.

1. Structural Strength and Load Capacity

The main consideration when creating high-capacity mooring bollards is their capacity to endure high loads. The forces exerted on the bollard result from vessel displacement and wind, waves, tides, and the dynamic vessel movements when the berthing process. Engineers need to calculate the maximum tension that a bollard will experience and add an adequate safety margin to handle unexpected conditions, like emergencies or storms. Finite element analysis as well as other techniques for structural modeling are commonly used to forecast the distribution of stress and to prevent the failure of a bollard under high load.

2. Material Selection and Durability

The selection of the material determines the strength and endurance of mooring bollards, its resistance to degradation of the environment. Cast iron, ductile iron and high-strength metals are frequently utilized for bollards that have high capacities due to their superior durability and tensile strength. In addition corrosion resistance is a major factor for marine applications. Galvanization, protective coatings or weathering treatment for steel are commonly used to extend the life of service and ensure the integrity of structures in saltwater conditions.

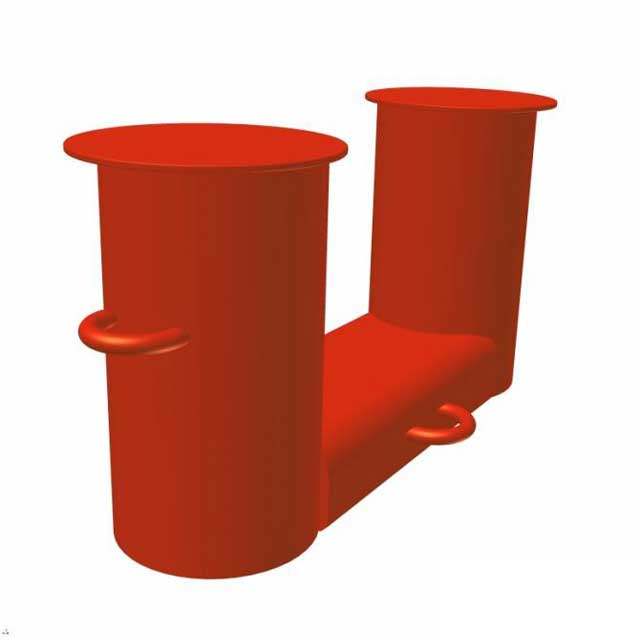

3. Geometry and Design Features

The design and shape of the bollard affect its function and efficiency of mooring. Bollards made of horn or staghorn permit numerous lines to be secured different angles. Tee-head or double-bitt bollards give flexibility for applications with high load. Designers should also take into consideration the ease of handling lines clearance requirements, as well as the risk of slippage or line chafing. Correct geometry makes sure that the lines used for mooring distribute the load evenly and decreases stress concentrations that can compromise the bollard structure or dock structure.

4. Integration with Dock Infrastructure

High-capacity marine mooring bollards must be securely fixed to the foundation of the dock or quay for mooring forces to be transferred safely. Integrating bollards into the structure underneath is vital in that a lack of load distribution could lead to the structural structure being damaged or failing. Engineers evaluate the strength of foundations as well as concrete thickness and patterns of reinforcement to ensure that the bollard’s function is in line with the design specifications.

5. Environmental and Operational Considerations

Environment-related conditions, including the tidal ranges, currents and winds, and the potential impacts from vessels, affect bollard design. Factors that affect operations, like the dimensions of vessels, frequency of docking, as well as the volume of traffic in ports, also affect bollard location and capacity needs. Designers must take into account these aspects in order to design safe, efficient and long-lasting mooring systems.

6. Compliance with Standards and Regulations

High-capacity marine bollards have to meet the international standards and those of regional countries in order to ensure safety for ships. The guidelines of organizations such as those of the International Association of Classification Societies (IACS) or local port authorities give guidelines for capacity of load installation, maintenance, and. Conformity ensures that ports can be able to safely house modern vessels and operate in accordance with recognized safety guidelines.

Types of High-capacity Mooring Bollards for Ultra-large Vessels

| Type of Bollard | Description | Key Advantages | Typical Applications |

| Horn (Staghorn) Bollard | The arms are curved, resembling antlers. | Secure multiple lines with steep angles Reduces slippage in lines. | Larger container ships bulk carriers oil tankers. |

| Tee-head (T-bollard) | It has a T-shaped head that is horizontal that is mounted on a vertical column. | It is versatile for line tensions up to high Easy to manage the mooring lines. | In general, port terminals for cargo and ports of commercial use. |

| Double Bitt Bollard | It is composed of two posts that are close to each other. | Helps support multiple line weights and spreads the load equally. | Megaports and terminals that handle huge vessels. |

| Single Bitt Bollard | Single vertical pole with the top being square or rounded. | Simple design; strong for single-line mooring. | Smaller terminals, or secondary line mooring. |

| Custom-engineered High-capacity Bollard | A custom-designed design that is based on the boat type, dock and the environmental conditions. | Optimized for high load and particular operational requirements. | Ports handling ultra-large vessels under unique environmental conditions. |

Applications of High-capacity Mooring Bollards in Modern Ports

| Application | Description | Benefits | Example Scenarios |

| Berthing Ultra-large Container Ships | Securing mega container vessels at berths. | Assists in stabilizing the vessel; helps prevent dock or hull damage. | Terminals handling 18,000-24,000 TEU ships. |

| Mooring Oil Tankers and LNG Carriers | Tankers that handle large tanks carrying the crude oil LNG as well as other large liquids. | Ensures safety when loading and unloading; allows for large line loads. | LNG terminals and ports for energy. |

| Bulk Carrier Operations | Secure bulk cargo vessels that carry grain, coal or even ore. | Distribute the forces of large cargo displacements; helps reduce stress on the dock. | Terminals for handling bulk materials. |

| Support for High-traffic Ports | Docking simultaneous for several large vessels. | Increases efficiency of operations; decreases wait times. | Mega container ports that have high berth usage. |

| Storm and Emergency Mooring | Secure mooring in severe weather conditions. | Increases safety; stops vessels from breaking off or drifting. | Ports are vulnerable to typhoons, hurricanes or strong tidal flows. |

| Specialized Industrial and Naval Applications | Secured vessels that are specialized, such as research vessels or naval vessels. | Design and capacity can be customized to meet specific vessel needs. | Research ports, military docks or shipyards. |

Future Trends in High-capacity Mooring Bollards for Ultra-large Vessels

Several key trends are shaping the design, functionality and deployment of high-capacity mooring bollards in modern port.

1. Advanced Material Technologies

The future bollards will likely contain high-strength corrosion-resistant alloys as well as composite materials. These developments will boost the capacity of load bearing while decreasing maintenance requirements. The latest coatings and treatments will increase the resistance to extreme marine environments, thus extending the life of bollards and increasing the reliability.

2. Smart and Sensor-Integrated Bollards

The integration of digital technology and sensors into bollards are an the latest trend. Sensors be able to monitor the tension of lines, forces in the environment and wear in real-time and provide port managers with relevant information to avoid over-loading and increase security. Smart bollards are also able to connect to ship-based systems to improve the mooring strategy, which can reduce time-to-market.

3. Optimized Structural Design

Future designs will utilize advanced computational modeling techniques, like finite element analysis as well as machine learning-based simulations to optimize the geometry and distribution of load. Bollards can manage greater loads more efficiently while reducing the use of materials and cost of construction.

4. Modular and Adaptive Solutions

Ports are likely to adopt bollards that are modular and can be expanded or adjusted in line with vessel size and traffic volumes alter. Flexible designs allow one berth to be able to accommodate a variety of vessel sizes and types increasing the flexibility of operations and efficiency.

5. Sustainability and Environmental Considerations

Sustainable design methods are increasingly crucial in the port infrastructure. The future bollards could use recycled or low-carbon materials and their placement will be designed to reduce the environmental impact on the surrounding port. Effective, durable designs minimize the need for frequent replacements, thereby contributing to the sustainability of the environment.

6. Enhanced Safety and Compliance Features

As standards for international standards change bollards with high capacity will continue to include elements that guarantee that they are in compliance with international safety standards. This is a result of design improvements which reduce the chance of structural damage or operational accidents, even in severe weather conditions.

Summary

High-capacity mooring bollards are crucial for the safe and efficient operation of ports handling ultra-large vessels. With careful design, material selection, and adherence to international standards, marine bollards ensure that ports can meet the ever-growing requirements of global maritime trade.