How to Ensure Mooring Chock Compliance in 2025

Over the past few years, the Panama Canal Authority (ACP) has started making safety and operational improvements for the vessels that transit through the canal, and for the most part, it is concentrating on the OP Notice to Shipping (N-1-2025) requirements regarding mooring equipment. In particular, mooring chock, Panama chock and closed chock.

If delays, operational safety concerns, and, in some cases, canal access are closed for repairs while en route to the canal don’t raise enough concern, the unsatisfactory mooring chocks will set the vessels back considerable funds and transit time. In the world of high mooring load challenges and risks, the design, certification, strength, and installation of chocks must be of high importance.

We will assist with how to determine mooring chock compliance, other relevant compliance international standards, compliance inspection steps, compliance enforcement methods, and remove some of the frequently asked questions from our compliance customers. These questions come from owners (shipowners), builders (shipyards), operators, and marine superintendents of our clients.

Table of Contents

What are the Mooring Chock Types and Their Regulatory Relevance?

1. Mooring Chock (General Purpose)

A mooring chock is a structural guide that controls the direction of a mooring rope, preventing abrasion and distributing load safely. General-purpose mooring chocks are found on most merchant vessels and come in open or closed versions. Their SWL (Safe Working Load) varies widely depending on vessel type.

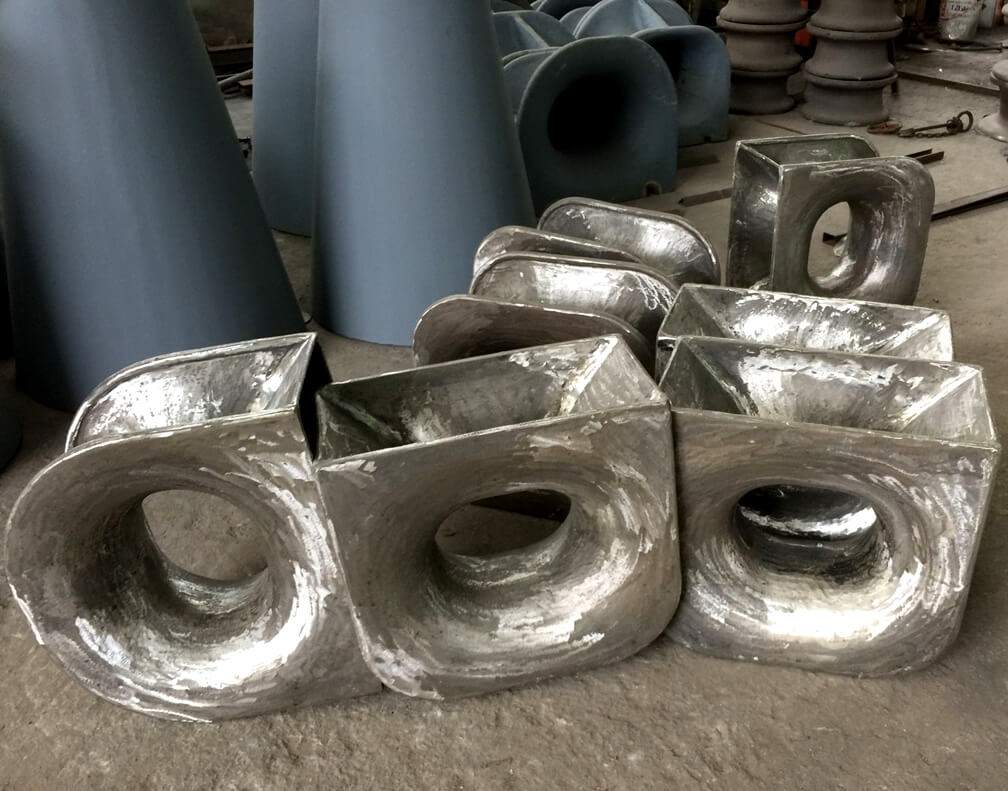

2. Closed Chock (ISO 13729)

The closed chock is widely used for high-load mooring applications. Fully enclosed and cast from high-strength steel, it reduces rope wear and ensures stable lead angles during berthing. Closed chocks following ISO 13729 are often accepted for Panama Canal transit if the SWL and dimensions meet requirements.

3. Panama Chock (ISO 13728)

A Panama chock is specifically designed for vessels transiting the Panama Canal. The ACP requires chocks used during towing and mooring operations to comply with ISO 13728. Their shape, opening size, and structural reinforcement are optimized to interface with canal locomotives, tugs, and terminal systems.

If a vessel intends to transit the canal, having certified Panama chocks is essential.

Key Requirements in OP Notice to Shipping N-1-2025 (Panama Canal Authority)

The ACP has clearly defined requirements for mooring chocks used during transit, including:

1. Chock Type & SWL Requirements

Only closed chocks or Panama chocks are acceptable for towing and mooring lines during transit.

Chocks must meet the minimum SWL specified in ACP rules, depending on vessel size (General Cargo, Panamax, Neo-Panamax).

2. Positioning & Number of Chocks

Chocks must be installed at specific locations to ensure proper lead angles. Missing or incorrectly positioned chocks can result in a failed inspection.

3. Identification & Documentation

Chocks must have:

- Permanent SWL marking

- Material grade information

- Class-approved drawings or manufacturer certificates

- Verification records for welding and installation

4. Inspection Outcomes

If a vessel fails ACP mooring equipment inspection, consequences may include:

- Transit denial

- Forced repairs at anchorage

- Additional survey fees

- Critical operational delays

Compliance is therefore not optional—it is a prerequisite for smooth passage.

International Standards to Consider (ISO, DIN, IACS & Class Rules)

Whether it’s Panama chocks or closed chocks, for selection, or installation, international compliance for standards, requirements, and compatibility with port safety and port structure remains critical. Panama chocks, specifically, have, among others, ISO 13728, which creates the most detailed standards framework. ISO 13728 establishes requirements for dimensions, materials, breaking load, and a series of standards. For the closed chocks and other mooring chocks, the standards and tolerances and mechanical properties are defined by DIN 81915/81906.

Manufacturing standards are not the only, albeit important ones. Regarding structure, other IACS draft standards, UR A2 and UR P2, are relevant and provide for the control of reinforcement, standard of welding, distribution of forces, and structure load for mooring fittings. For retrofitting and new ship builds, ALL chocks are required to obtain sanctioning from a qualified classification society, i.e., ABS, DNV, LR, BV, CCS, etc. These class rules are to ensure the SWL does not result from assumption, the installation and relevant structure are adequate, and barriers still exist for safety.

Vessels transiting the Panama Canal and other similar restricted or regulated areas, for example, the Panama Canal Authority (ACP) requirements must be met to ensure no operational hold-ups or fines are incurred.

How to Perform a Compliance Assessment on an Existing Vessel

To ensure that existing mooring chocks, including Panama chocks and closed chocks, follow international mooring chocks, a documented assessment should be made, particularly for those planning to cross regulated routes like the Panama Canal and those undergoing class renewal surveys. Below is a standardized compliance process used by charterers and class societies.

Step 1 — Documentation Collection

Collect all technical documentation for each of the chocks, including general arrangement and section drawings, SWL markings, material certificates, manufacturer data sheets, welding procedure specifications, installation reports, and archived surveys. Document deficiency is a cause of delay and denial of ACP (Panama Canal Authority) inspections.

Step 2 — Perform On-board Inspection

Thoroughly inspect all of the chocks physically. Do the chock opening dimensions conform to the relevant ISO standard? Do the lead angles check so that the mooring line can be used with minimal bending and friction on it? Are the internal, particularly closed chock, surfaces smooth enough to reduce wear on the synthetic rope? Document and photograph all of the chocks showing evidence of corrosion, paint peel, wear, and structurally altered welds, and where the welds were made on the reinforcing plates. All findings should be tagged and used to support the developing compliance record.

Step 3: Determine if the Panama Canal is Right for You

If the vessels that utilize Panama chocks, ensure that the requirements of ISO 13728 are being met for geometry and load capacity. For closed chocks, conform to the requirements of ISO 13729. Also, ensure that the chock’s position meets the ACP’s towing and mooring operational requirements.

Step 4: If in Doubt, Get a Class Surveyor

If there are any doubts, regardless of having doubts about the SWL, the welding of the structure, and the structural reinforcement, obtain a class surveyor. Changes to the mooring chocks, whether to reposition or add a retrofit, often require the approval of a classification society, as well as updated certificates.

Step 5: Prepare the Compliance Report

Once everything is ready, prepare a compliance report that contains a structure of the inspection documents, pictures, measurements of dimensions, SWL affirmation, and classification society endorsement. This is to prove compliance and for the final clearance to cross the Panama Canal.

How to Upgrade or Replace Mooring Chocks for Compliance

Equipment must be updated or changed to mooring chocks when international standards and operational requirements are not met. This includes all chock types, Panama chocks, and closed chocks, especially for vessels prior to canal transits and during class renewal surveys.

1. When an Upgrade Is Required

Replacement is advised if the chock’s Safe Working Load is below ACP requirements, if opening dimensions fail to meet ISO tolerances, or if visible deformation, cracking, or excessive wear is present. Reinstallation is also necessary when the chock is misaligned or when key documentation, such as certificates or drawings, cannot be verified.

2. Choosing the Right Type of Chock

For operations at the Panama Canal, a certified Panama chock (ISO 13728) is mandatory. If a vessel has a high-tension mooring, select closed chocks that are ISO 13729 compliant to ensure better protection of the mooring lines. For mooring of a more general purpose, depending on the load patterns and the leads, either open or closed designs can be acceptable.

3. Fabrication & Welding Requirements

The replacement chocks must be chocks that have been made using high-strength cast or forged steel, along with adhering to an approved WPS. Nondestructive testing, such as ultrasonic testing, magnetic testing, or penetrant testing, is mandatory, and to reduce rope wear, internal surfaces must be smooth.

4. Certification & Documentation

Every upgraded chock must include a valid Material Test Certificate, clear SWL markings, class approval, and fabrication or proof-load test records to ensure compliance.

Best Practices for Long-Term Compliance & Mooring Safety

1. Maintenance & Inspection Schedule

To maintain compliance and safety:

- Conduct visual inspections monthly

- Inspect after every tug operation

- Repaint and repair corrosion promptly

- Clean the chock opening to avoid rope damage

2. Rope Interaction & Wear Reduction

Excessive wear often occurs when mooring lines pass through a Panama chock or closed chock at incorrect angles. Operators must verify that all lines follow the vessel’s approved mooring plan, maintaining proper lead angles to avoid overload, crushing forces, or accelerated rope degradation.

3. Crew Training & Operating Procedures

Safety Management System (SMS) should include:

- Correct use of Panama chocks during transit

- Safe mooring line tension management

- Emergency mooring procedures

A trained crew significantly reduces operational risks.

Cost, Downtime, and Procurement Considerations

Upgrading mooring chocks, including Panama chocks and closed chocks, requires evaluating both equipment cost and shipyard downtime. Standard class-approved Panama chocks typically range from USD 1,200–4,500, while heavy-duty closed chocks used in high-tension mooring can cost USD 1,500–6,000 depending on size, material grade, and certification. Installation and welding expenses vary by shipyard and may increase if structural reinforcement is required.

1. Downtime Planning

Most retrofit projects take 1–3 days, with shorter schedules possible when replacing chocks with identical dimensions and bolt or weld footprints. Proper planning minimizes impact on vessel operations.

2. Choosing a Reliable Supplier

It would be to your advantage to select manufacturers with ISO certification, a shipyard with reliable references, authentic class approvals, and fast delivery. A good supplier is someone you can trust, and you’ll have reduced risk and assured reliability.

To Sum Up

Complying with the Mooring Chock Requirements has become crucial for international vessels, in particular, those vessels crossing the Panama Canal. Knowing the types of chocks, adhering to ISO, complying with the ACP rules, and keeping the documentation in order can save shipowners time and money, along with fastening the mooring on the vessels. A methodical inspection and an upgrade plan can provide long-term operational continuity and compliance with the rules and regulations.

FAQ (Frequently Asked Questions)

Q1: Does every vessel entering the Panama Canal need Panama chocks?

Not always, but any chock used for towing or mooring during transit must meet Panama chock or closed chock standards, as verified by ACP.

Q2: Can a closed chock replace a Panama chock?

Yes, if it meets ISO 13728 dimensional and SWL requirements and is approved by ACP or class.

Q3: How do I confirm my chock is class-certified?

Check for class-stamped SWL marking, manufacturer certificate, and welding documentation. Without documentation, a re-survey is required.

Q4: What happens if my chocks fail ACP inspection?

Transit may be denied, the vessel may be detained, and additional inspection or repair costs will apply.

Q5: How often should chocks be inspected?

At least monthly, plus after heavy mooring operations, tug assistance, or any unusual loading event.

Q6: Can damaged chocks be repaired instead of replaced?

Minor wear can be repaired, but structural damage, cracks, or insufficient SWL typically require replacement.