How to Customize Marine Anchors for Different Vessel Types

Marine anchors have proved pivotal to the operational safety and effectiveness of almost any vessel. These anchors have the ability to defend a ship from drifting, almost like belts on a human. They also provide a sense of security and stabilization within the ship during times of mooring or other emergencies. Unlike what most people think, marine anchors do not serve the same purpose on every vessel. The effectiveness of anchors depends on the type and purpose of the ship. Customizing marine anchors to the requirements of different vessel types ensures safety, effectiveness, and reliability in a variety of marine settings.

Table of Contents

Importance of Marine Anchor Customization

Every vessel operates under unique conditions. Whether it’s an ocean cargo ship with countering open ocean currents, a yacht meant for leisurely relaxing while moored in shallow bays, a fishing trawler anchoring in regions with convenient variable sandy seabeds, or anything between and beyond. Customization enables marine anchors to take into consideration the parameters of size and displacement of the vessel, the kind of seabed, and operational function. The right anchor will reduce wear while optimizing holding power and minimizing chances of dragging.

Key Factors Influencing Marine Anchor Design for Different Vessel Types

Knowing the various factors that affect allocation of anchors to specific ships is important for ship builders and operators aiming to optimize durability and performance.

1. Vessel Size and Displacement

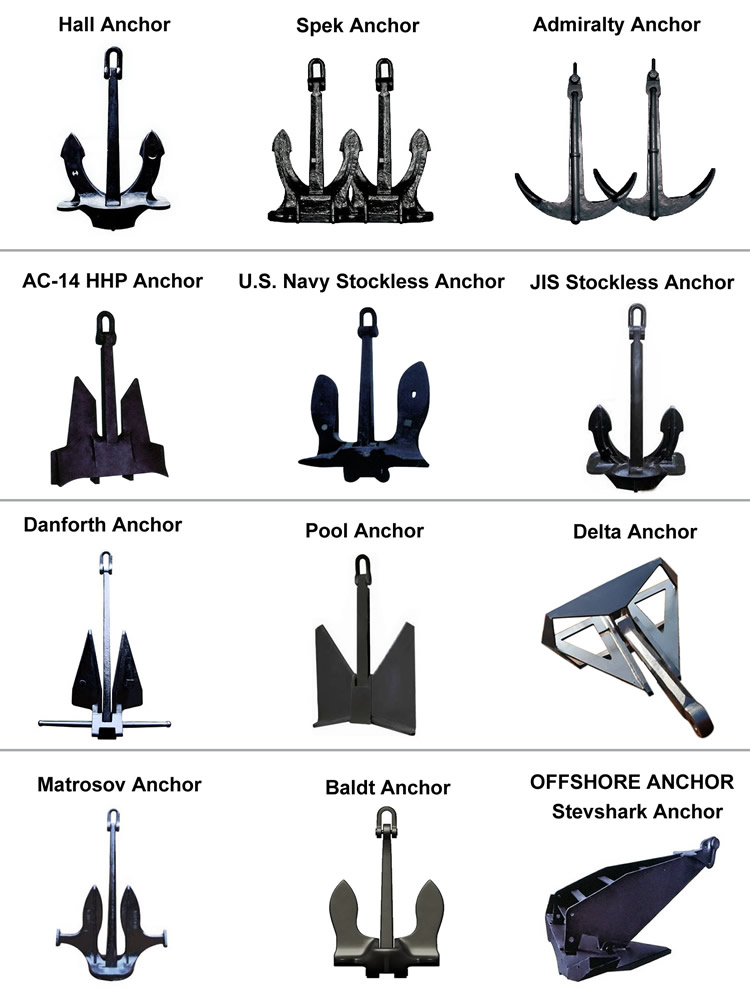

The size and weight of a vessel significantly shape the design of marine anchors. For instance, the big commercial ships carrying containers or tankers, face strong winds, current and waves and thus require anchors that are capable enough to withstand such huge forces. On such ships, heavy-duty anchors, such as the AC-14 or stockless designs, more often than not customized with enhanced reinforced steel, optimized fluke geometry, and increased weight so as to maximize the holding power. Yachts and recreational boats, on the other hand do not need such huge anchors, as their focus is on ease of handling, compact storage and holding power.

2. Seabed Conditions

The Seabed characteristics, including mud, sand, rock and the mixture of all, greatly determines the design of anchors. Different Seabed require different fluke widths, shank lengths and a specific weight distribution for optimal grip. Fishing vessel fluke style anchors that are more readily available than others benefit on purpose designed fluke, mud or sand anchors with wider blades that can penetrate blades more easily. Anchors for offshore vessels, working in heavy, muddy, bottom-seas need heavy-duty anchors designed for high holding power, deep penetration and lateral drag resistance, for offshore stability.

3. Operational Requirements

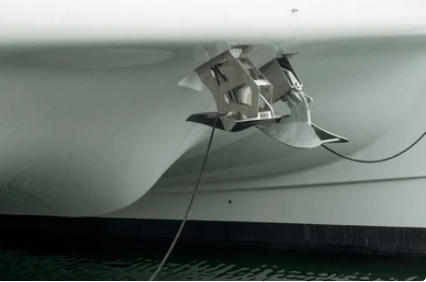

The intended operational use of a vessel also affects anchor customization. Naval vessels must operate in diverse environments, ranging from shallow harbors to rocky shores, necessitating modular anchors made of advanced alloys with coatings that minimize magnetic signatures. Offshore supply vessels and tankers often rely on anchors compatible with automated deployment systems, allowing smooth handling while maintaining holding strength under heavy loads. Recreational yachts prioritize anchors that are lightweight, compact, and easy to deploy while still providing reliable performance in varied marine environments.

4. Regulatory Compliance and Safety Standards

Marine anchors are subjected to varying degrees of compliance with international regulatory standards, including those from classifying societies such as ABS, DNV, and Lloyd’s Register. The standards indicate the materials to be used, the structures to be formed, and the holding capacity of the anchors. Compliance with these standards is necessary to achieve operational and safety effectiveness. These standards are of utmost importance to large scale commercial and offshore vessels, particularly in cases of extreme operational conditions.

5. Material Selection and Durability

The choice of material greatly determines the performance and longevity of marine anchors. For the large and offshore anchors, high strength steel and specially formulated alloys are used as they provide excellent toughness and high resistance to deformation. For recreational crafts, the use of stainless steel and certain coated alloys improves the aesthetic appeal of the vessel while increasing the longevity of the components. Other materials and composites are also being considered to construct lightweight anchors with high strength to allow better performance of the vessel without carrying excessive weights.

6. Environmental and Technological Considerations

Recent designs of the anchors have started to incorporate new technology along with environmental considerations. Anchors that have been fitted with smart technology and sensors can calculate real time the performance and status of the anchor in relation to the seabed, increasing safety. Designs that are considered to be sustainable have reduced impact on the seabed in order to protect the marine life and still provide the reliable anchoring that is needed. Material science advances along with computer simulations allows the designer to mark and optimize the anchors before they are sent to be produced.

Custom Marine Anchors for Different Vessel Types

| Vessel Type | Anchor Type(s) | Customization Focus | Key Advantages |

| Large Commercial Ships | AC-14 Anchor, Stockless Anchor | High-strength steel, optimized fluke and shank design, compatibility with automated anchoring systems | Extremely high holding power, durable for heavy displacement and mixed seabeds |

| Cargo and Container Ships | Stockless Anchors | Reinforced materials, optimized fluke shape | High holding power, durable in mixed seabeds |

| Oil Tankers and Offshore Vessels | High-Holding-Power (HHP) Anchor | Deep penetration for mud/clay, drag resistance, compliance with offshore standards | Secure positioning in offshore operations |

| Fishing Vessels | Danforth (Fluke) Anchor | Wide flukes, lightweight, easy deployment | Strong grip in sandy/muddy seabeds |

| Yachts and Recreational Boats | Plow Anchor, Claw Anchor | Compact, corrosion-resistant, aesthetic finishes | Easy handling, reliable in varied seabeds |

| Navy and Military Vessels | Modular/Specialized Anchors | Advanced alloys, stealth coatings, adaptable designs | Reliable in diverse seabeds, multifunctional performance |

Emerging Trends in Custom Anchor Design for Different Vessel Types

The latest trends in marine anchor design are focusing on new materials and smart design integration for enhanced durability and improved safety and performance in shipping, leisure and defence marine activities.

1. Advanced Materials for Lightweight Strength

In custom design, the use of advanced materials in marine anchors to reduce weight without compromising holding power is one of the most prominent trends. Anchors, and specifically large commercial ships or tankers, used to be designed with massive blocks of steel for due to the strength it provided. However, high strength alloys and composite materials are becoming more widely used, which possess lighter weight offerings, holding even greater capabilities. This innovation is especially beneficial for yachts and smaller vessels, which need the ease of handling and storage without compromising performance.

2. Smart Anchors with Integrated Sensors

There have also been technological innovations in smart anchors which possess the ability to monitor holding performance and seabed conditions with the use of sensors in real-time. These capacities can recognize anchor shift, the type of seabed, and load, and the ability to relay them to the ship’s control system. This is especially useful for offshore supply vessels, oil tankers, and even naval ships since it gives guides that improve the accuracy of anchor deployment, drag, and overall operation safety.

3. Environmentally Conscious Designs

An important factor to consider when designing an anchor is its sustainability. Different forms of anchoring can cause disruption to the underwater environment and sea beds with coral and sea grass. New anchor designs attempt to mitigate the impact on the sea bed using fluke shapes and materials that minimize penetration while still holding. This concern is becoming more and more common with recreational yachts as well as coastal vessels that travel in environmentally sensitive waters.

4. Modular and Versatile Anchors

Customization includes the ability to develop modular anchors capable of being configured to suit various types of vessels and different seabed conditions. Naval and military vessels, for instance, require anchors capable of operating in and out of diverse ecosystems, from rocky coast lines to sandy beaches. Modular designs add to the anchor a variety of sections, such as the flukes and the shank, which can easily be tailored to meet different operational demands. This versatility augments performance.

5. Integration with Automated Anchoring Systems

For commercial and offshore vessels, anchor design is integrated with other systems for automation. Modern custom anchors are designed to be used with automated systems for deployment and retrieval. This promotes seamless operation for large vessels such as container ships and oil tankers. Also, the anchor’s design improves efficiency and decreases the chance of error during anchoring to reduce the load on the crew.

6. Aesthetic and Corrosion-Resistant Features for Recreational Vessels

Anchors used for recreational vessels have different intended uses than anchors intended for commercial or offshore vessels. Current anchors designed for recreational vessels have aesthetically pleasing shapes, polished surfaces, and compact sizes for limited onboard stowage, along with dependable performance in a variety of seabed and bottom conditions. This includes anchors designed for emerging boating trends. These trends may include recreational and leisure boating, positioned for stowage even in minimal onboard space.

Summary

It is essential for safe and effective maritime work to customize marine anchors for different vessel types. The designs of anchors when adjusted to the vessel’s features and the surrounding working conditions to be faced during the voyage provide assurance of dependability in any body of water. The evolution of shipping, fishing, recreational activities, and defense worldwide is also centered on the diversification in materials and technologies and marine anchors that are designed to support the varied requirements.