Cost-effective Solutions for Marine Anchors

All ships, oil rigs, fishing boats, and recreational boats need marine anchors for safety and stability. Anchors provide safety in different situations. But, manufacturers, installers, and maintainers of anchors charge a lot which is why we need cost-effective solutions in marine anchors. In the maritime industries for boats and oil-rigs, we need anchors for oil-rigs and we can’t give up on safety, performance, and value.

Table of Contents

The Costs in the Manufacturing of Marine Anchors

This chart highlights the primary cost drivers and their influence on the total manufacturing cost of marine anchors, helping manufacturers identify areas where cost-effectiveness can be optimized.

| Cost Component | Description | Impact on Overall Manufacturing Cost |

| Raw Materials | Steel, high-strength alloys, composite materials, coatings | Major cost driver; quality affects durability and performance |

| Design and Engineering | R&D, anchor geometry optimization, simulation testing | High upfront cost but reduces long-term operational expenses |

| Fabrication and Machining | Cutting, welding, forging, casting, CNC machining | Labor- and energy-intensive; efficiency reduces total cost |

| Surface Treatment & Coating | Anti-corrosion coatings, galvanization, polymer coatings | Adds to upfront cost but extends lifespan and reduces maintenance |

| Quality Control & Testing | Non-destructive testing, load testing, compliance checks | Essential for safety; contributes moderately to cost |

| Packaging and Transportation | Secure packaging for shipping; logistics to ports or customers | Depends on anchor size and weight; impacts final price |

| Maintenance & Lifecycle Planning | Consideration of service schedules, refurbishments, and repair programs | Not part of initial manufacturing but influences total cost of ownership |

| Tooling and Equipment | Investment in machinery, molds, and automation systems | High initial investment; reduces per-unit cost with scale |

| Overhead Costs | Facility, utilities, administration, and management | Indirect cost that contributes to overall manufacturing expenses |

Why Need Cost-effective Solutions in Marine Anchors

Ensuring Operational Efficiency

Marine anchors, used in different environments, for the marine safety is a requirement for any vessel, and any boat. But, if boat and oil-rig operators have dull, inefficient, and clunky anchors, then water fuel and time will be wasted. The optimal safety and style of the anchor will help the vessel maintain balance and stability, and save operational efficiency. Hence, the shipping operations will be cost-efficient.

Reducing Capital Expenditure

Quality anchors, meaning cost-efficient, are key anchors designed, but cost is relative. The initial amount of anchors as a vessel is any vessel owners huge upfront cost. But, cost-efficient anchor design will lessen this amount as well. The balance of safety and cost efficient anchors are designed in the latest styles.

Enhancing Safety and Reliability

When an anchor fails, it can lead to some very serious problems like a boat drifting out of control, grounding, or getting into a collision. Integrating better smart monitoring and predictive maintenance designed to be more cost effective assists in the prevention of an expensive accidents, protecting the boat, and saving the marine environment. All of this can be done while staying inexpensive.

Supporting Environmental and Regulatory Compliance

Tighter environmental regulations require the use of anchoring systems that prevent pollution, protect the seabed, and minimize other environmental impacts. Cost-effective anchors designed with environmental sustainability principles provide operational ecological and economic benefits by reducing the potential costs of regulatory remediation, expanding operational zones, and reducing potential remediation costs.

Facilitating Technological Integration

New marine operations depend on digital monitoring systems and automated positioning systems. Cost-effective anchors adaptable to modern integration operated and controlled systems allow digital monitoring of anchoring systems to prevent misuse, mitigage excess stress on anchoring systems, enhance operational control, and reduce costs.

Key Strategies for Cost-effective Solutions in Marine Anchors

1. Leveraging Advanced Materials

This chart highlights how material innovations improve durability, reduce weight, lower maintenance, and support sustainable practices in marine anchor design.

| Material Type | Key Innovations & Characteristics | Benefits for Marine Anchors | Typical Applications |

| High-strength Alloy Steel | Optimized alloy composition for higher tensile strength | Reduces anchor weight while maintaining holding power; durable | Commercial vessels, offshore rigs |

| Corrosion-resistant Steel | Stainless steel or galvanization techniques | Resists rust and seawater corrosion; extends service life | Recreational boats, coastal vessels |

| Composite Materials | Fiber-reinforced polymers, hybrid composites | Lightweight, corrosion-resistant, easier handling | Small vessels, eco-friendly moorings |

| Surface Coatings | Epoxy, polymer, or specialized anti-corrosion coatings | Prevents wear and marine growth; reduces maintenance | All anchor types across environments |

| Recyclable Materials | Sustainable metals and polymers | End-of-life recycling reduces disposal costs | Environmentally sensitive marine areas |

| Hybrid Material Anchors | Combination of metals and composites | Balances strength, weight, and durability | Offshore renewable platforms, mixed seabeds |

2. Optimizing Anchor Design

Design optimization plays a critical role in achieving cost-effectiveness.

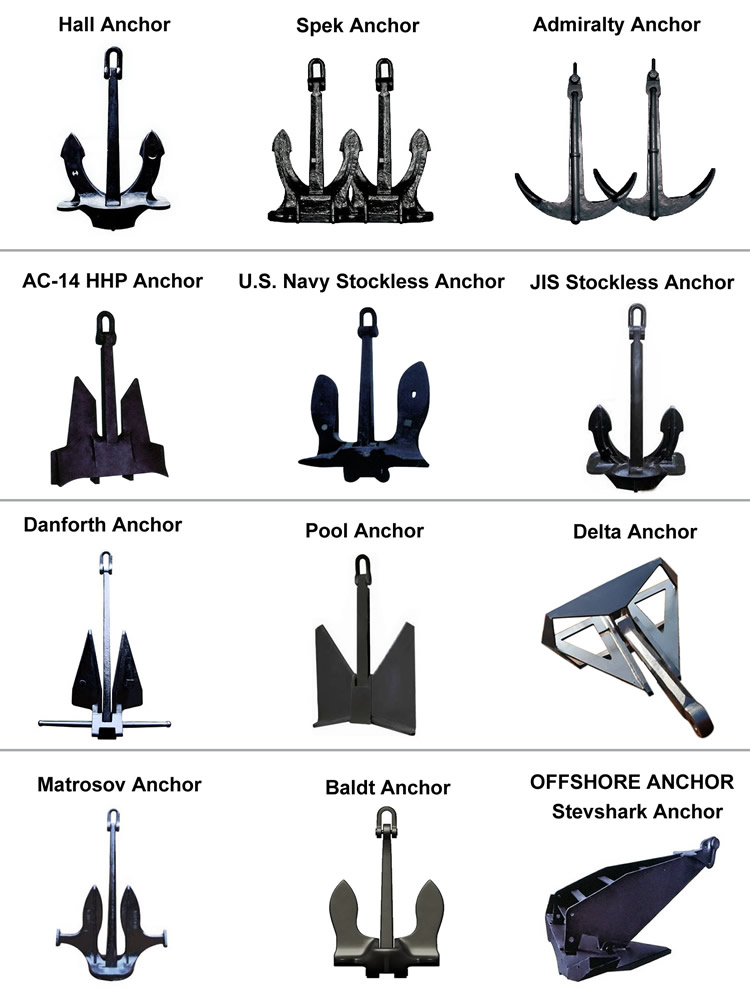

This chart provides the innovative features, their practical advantages, and the specific marine applications where each anchor design excels.

| Anchor Design Type | Key Features & Innovations | Advantages Over Traditional Anchors | Ideal Applications |

| Fluke Anchor (Danforth) | Wide flukes for digging into seabed; lightweight design | High holding power-to-weight ratio; easier handling | Small to medium vessels, soft seabeds |

| Claw Anchor (Bruce) | Curved fluke design for quick setting | Reliable in varied seabed types; self-righting | Recreational boats, sandy/muddy bottoms |

| Delta Anchor | Plow-shaped blade; high penetration capability | Strong holding in hard or mixed seabeds; efficient reset | Offshore vessels, commercial shipping |

| Mushroom Anchor | Dome-shaped base for burying in soft seabeds | Very stable in soft or muddy bottoms; long-term mooring | Floating platforms, buoys, permanent moorings |

| Stockless Anchor | Compact, heavy shank; easy stowage | Simplifies handling on large ships; versatile | Large cargo ships, naval vessels |

| Modular Anchor | Components can be replaced individually | Reduces replacement costs; adaptable to different conditions | Fleets with varied vessel types |

| Eco-friendly Anchors | Designed to minimize seabed damage; made of recyclable materials | Complies with environmental regulations; reduces fines | Marine protected areas, offshore projects |

3. Streamlining Manufacturing Processes

How manufacturing processes are executed affects the price of anchors. Automated welding, CNC machining, and precision casting are some ways to not only decrease labor and production time, but also maintain to a certain degree the quality of the product. Standardization also further reduces procurement and inventory costs. When a manufacturer improves their production technique, they are able to offer anchors of better quality at a lesser price.

4. Incorporating Smart Technologies

The use of digital controls and monitoring systems is a new system for cost saving anchors. Equipment failure and costly accidents are avoided because sensors monitor several important parameters in real time. Predictive maintenance systems also save time by eliminating unnecessary downtimes. Dynamic positioning system compatibility is also an important feature. This system ensures operational inefficiencies are reduced by eliminating unnecessary movements during anchor operations.

5. Emphasizing Lifecycle Management

In order to achieve cost effective anchoring, long short term expenses must be considered. When an anchor is regularly inspected, appropriately handled, and fully refurbished, the expense of an anchor replacement is avoided. This anchor priced replacement expense is now considered long term. These strategies are important to shipowners because they plan maintenance budgets effectively and eliminate unexpected expenditures.

6. Prioritizing Sustainability

When it comes to reducing costs, sustainability can be integrated and considered. Having an environmentally friendly anchor that reduces impact to the seabed will keep you legally compliant, and stop you from incurring remediation costs, fines, and lawsuits. The use of recyclable materials and environmentally friendly eco coatings will guarantee positive residual value at an anchor’s end of life. The positive operational limits of sustainable designs also give extended use from an ecological standpoint combined with an economically sustainable use.

Final Thoughts

Achieving cost-effective marine anchors includes the integration of new materials, effective design, clever technology, and sustainable methods. Ship operators and the offshore industries make savings while preserving safe and dependable anchoring by working on long-term maintenance, environmental compliance, and anchor durability to address ongoing costs and eliminate backward thinking on upfront costs.