Designing Effective Marine Watertight Doors: What are Key Principles and Considerations

The design and performance of marine doors are critical in safeguarding vessels from potential threats in the maritime industry, where safety is vital. Marine watertight doors are crucial components in protecting the safety and integrity of ships at sea. They are specifically designed to resist water penetration during emergencies or severe situations. This article goes into the design concepts that make marine watertight doors successful water-tight doors.

Purpose and Importance of Marine Watertight Doors

Watertight doors are deliberately positioned throughout a ship’s structure to compartmentalize it. Their major function is to contain flooding in the case of damage while retaining the buoyancy and stability of the vessel. These marine watertight doors are critical because they operate as barriers that limit the movement of water, averting catastrophic effects in emergencies.

Key Considerations and Design Principles of Marine Watertight Doors

Marine watertight door design involves a combination of engineering expertise, adherence to safety regulations, and a deep understanding of the challenging marine environment.

1. Material Selection

Corrosion Resistance: Because of the saltwater exposure, marine settings are corrosive. The use of corrosion-resistant materials such as marine-grade stainless steel, aluminum alloys, or other corrosion-resistant materials ensures the longevity and structural integrity of watertight doors.

Durability: The materials chosen must be able to endure the physical loads and impacts encountered during routine operations as well as emergency scenarios.

2. Sealing Mechanisms

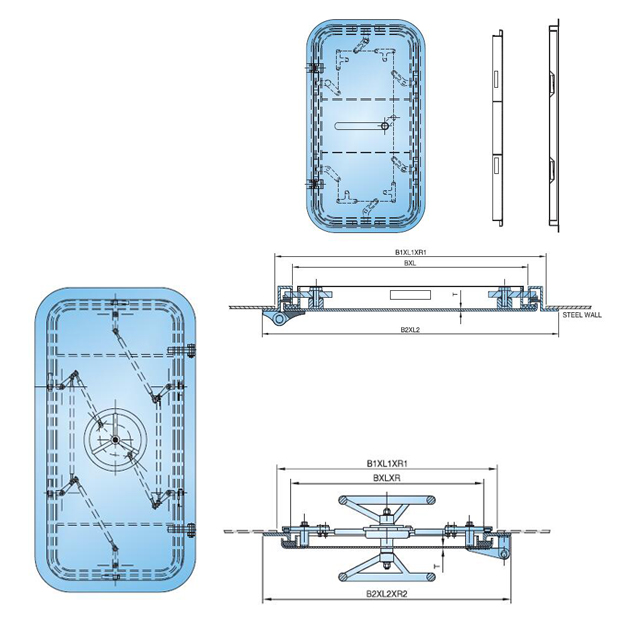

Compression Gaskets: Compression gaskets, an important component of watertight doors, form a tight seal when the door is closed, preventing water infiltration. These gaskets are often comprised of tough materials that retain their effectiveness even when subjected to high pressure.

Inflatable Seals: Some advanced designs inflatable seals that can adjust to different pressures, adding an extra layer of protection against water entry.

3. Hinges and Locking Systems

Heavy-Duty Hinges: Watertight doors are frequently opened and closed. Heavy-duty hinges are required to ensure durability and longevity, as well as optimum alignment and performance.

Secure Locking Mechanisms: To avoid unintended door openings during normal operations or emergency scenarios, locking mechanisms must be reliable and secure.

4. Testing and Certification

Rigorous Testing: Watertight doors are rigorously tested in order to imitate real-world conditions such as high-pressure water flow and shifting sea states. These tests confirm the doors’ capacity to maintain their waterproof integrity under various conditions.

Certification Compliance: Watertight doors meet the required safety and performance criteria when they adhere to international norms and regulations, such as those defined by the International Maritime Organization (IMO).

5. Design for Easy Operation

Ergonomics: Consideration for ease of operation is essential, especially during emergency situations where quick and efficient closure of watertight doors is crucial.

Accessibility: Watertight doors should be designed to be easily accessible and operable by the crew, considering factors like size, weight, and the need for manual or automated operation.

6. Integration with Automation

Remote Monitoring and Control: Automation technologies enable remote monitoring and control of watertight doors. This allows for real-time status updates and quick responses to emergency situations, enhancing overall operational efficiency.

7. Maintenance Protocols

Regular Inspection: Scheduled inspections and maintenance protocols are vital to identifying and addressing issues promptly. Regular lubrication of hinges and testing of sealing mechanisms help ensure ongoing watertight integrity.

Training: Proper training of crew members on maintenance procedures and emergency protocols ensures that marine doors are well-maintained and function effectively when needed.

8. Environmental Considerations

Temperature Variations: Watertight doors should be built to endure the temperature fluctuations that are frequent in marine situations without compromising their sealing capabilities.

UV Resistance: UV-resistant coatings or materials should be considered if doors are exposed to sunlight to prevent deterioration over time.

Conclusion

Watertight design for marine doors is crucial for maritime safety, since these doors serve as the first line of defense against potential flooding. Watertight doors play an essential part in guaranteeing the safety and resilience of vessels at sea by using painstaking material selection, adhering to rigorous testing and certification, and incorporating modern sealing technology. The continued commitment to watertight door design remains vital to the overall safety and security of seafaring vessels and their people as the maritime sector evolves.